bucket crusher for excavator

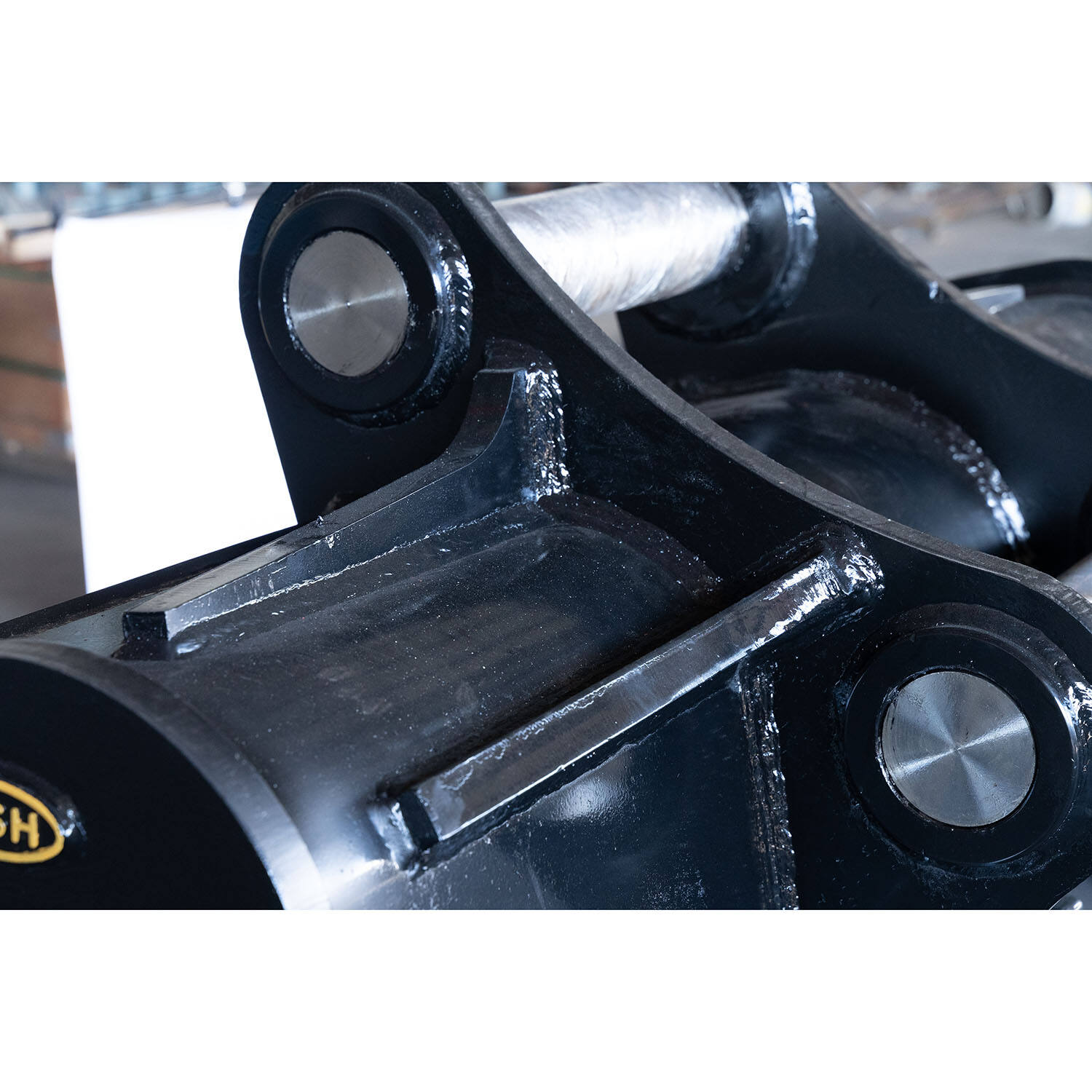

A bucket crusher for excavator is an innovative attachment that transforms standard excavators into efficient on-site crushing machines. This versatile equipment enables direct crushing of construction materials, including concrete, asphalt, stone, and other demolition debris, right at the worksite. The system features a robust jaw crushing mechanism integrated into a bucket design, powered by the excavator's hydraulic system. The crushing jaws are typically made from high-wear resistant materials, ensuring durability and consistent performance under demanding conditions. With adjustable output sizes ranging from 20mm to 120mm, operators can precisely control the final product size according to specific project requirements. The bucket crusher incorporates advanced safety features, including an automatic anti-lock system and overload protection, ensuring safe operation even in challenging conditions. Its unique design allows for easy material loading and efficient crushing cycles, significantly reducing the need for traditional crushing equipment and material transportation. The system also features integrated magnetic separators for removing steel reinforcement from concrete, making it particularly valuable in demolition and recycling applications.