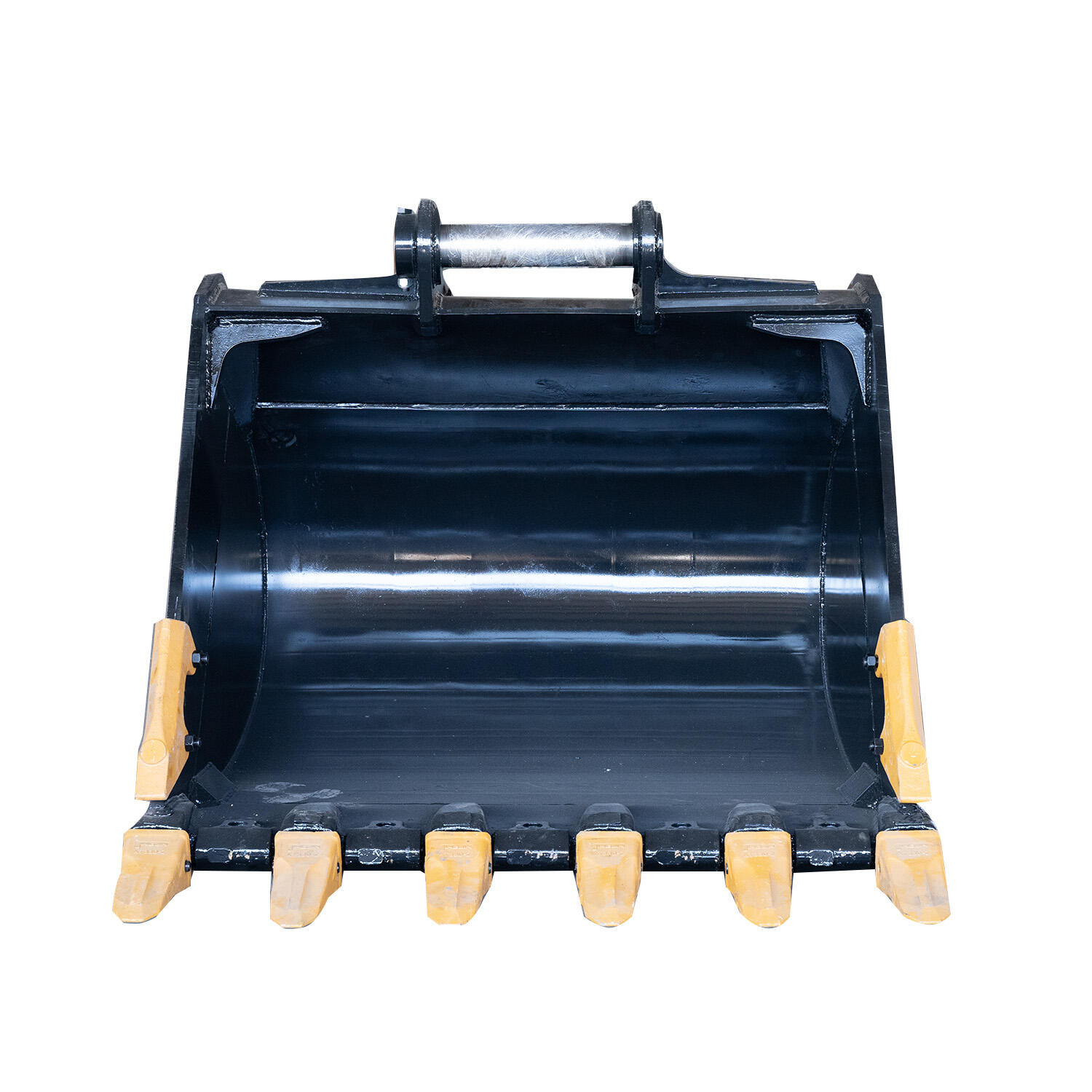

rock excavator bucket

The rock excavator bucket is a specialized attachment designed for heavy-duty earthmoving and mining operations, engineered to withstand the most demanding excavation tasks. This robust piece of equipment features reinforced steel construction with wear-resistant materials, specifically designed to break through and handle hard rock, consolidated materials, and challenging terrain. Its unique tooth configuration and optimal geometry ensure maximum penetration force while maintaining structural integrity during operation. The bucket incorporates advanced wear plates and protective elements strategically positioned to extend service life and reduce maintenance requirements. With various sizes available ranging from compact to large-scale operations, these buckets are equipped with specialized cutting edges and reinforced corner protectors that enhance performance in extreme conditions. The design includes carefully calculated curves and angles that optimize material flow and prevent clogging during operation, while special alloy steel components ensure durability in high-impact scenarios. Modern rock excavator buckets also feature advanced coupling systems for quick attachment changes and improved safety mechanisms for secure operation. These buckets are essential in quarrying, mining, construction, and infrastructure development projects where efficiency in handling hard materials is crucial.