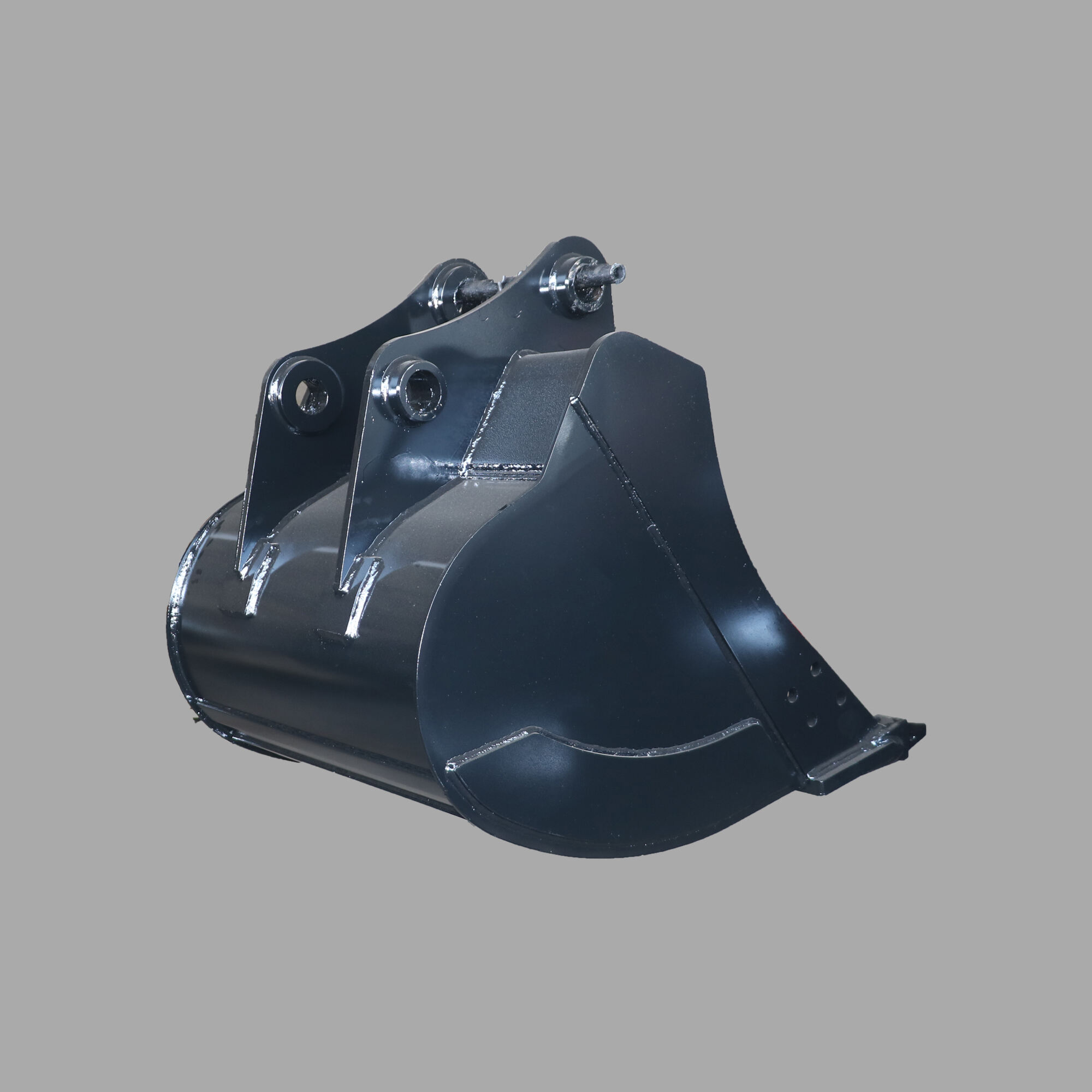

cat digging bucket

The Cat digging bucket represents a pinnacle of earthmoving equipment engineering, designed specifically for Caterpillar excavators and backhoe loaders. This essential attachment features a robust steel construction with reinforced wear points and a specialized tooth design that optimizes penetration force while maintaining structural integrity. The bucket's capacity ranges from 0.5 to 3.5 cubic meters, accommodating various job requirements from precise utility work to heavy-duty excavation. Advanced features include a curved floor design that facilitates material flow and reduces material retention, while side cutters provide enhanced digging efficiency. The bucket incorporates wear strips and protective plating in high-impact zones, significantly extending its operational lifespan. Engineered with precise weight distribution, it maintains optimal balance during operation, reducing stress on the excavator's boom and improving fuel efficiency. The attachment system ensures quick coupling and decoupling, minimizing downtime between tasks. This versatile tool excels in applications ranging from general construction and pipeline installation to mining operations and landscape grading, making it an indispensable asset for construction professionals seeking reliability and performance.