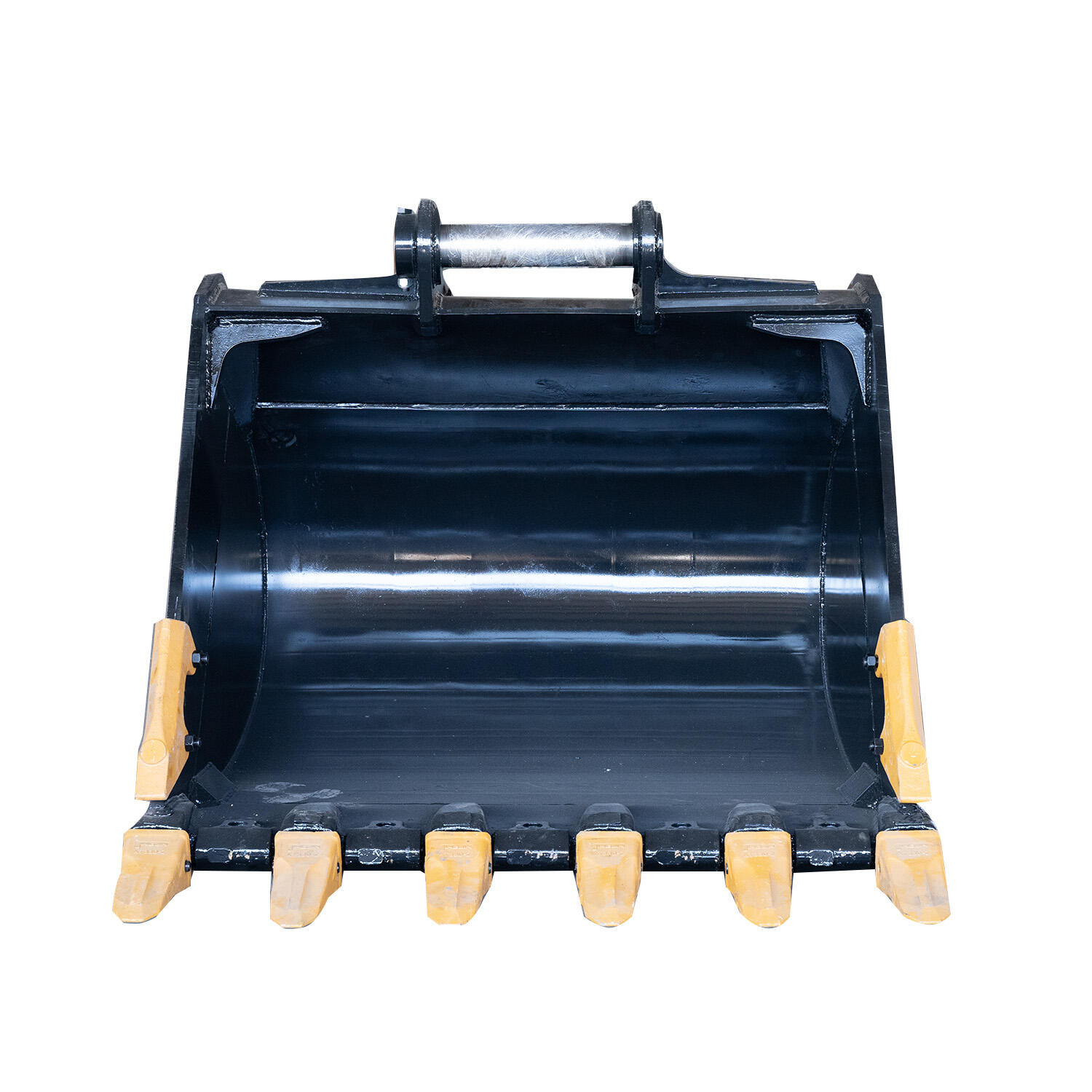

rock teeth for excavator

Rock teeth for excavators are essential attachments designed to enhance the digging and breaking capabilities of construction equipment. These hardened steel components attach to the excavator bucket's leading edge, providing increased penetration power and wear resistance during heavy-duty operations. Engineered with high-carbon alloy steel and advanced heat treatment processes, these teeth feature a self-sharpening design that maintains optimal performance throughout their service life. The teeth come in various profiles and sizes to match different soil conditions and applications, from general earthmoving to heavy rock breaking. Their unique geometry ensures maximum material penetration while minimizing energy consumption and reducing bucket wear. The attachment system typically includes a robust adapter system that allows for quick replacement when needed, reducing maintenance downtime. Modern rock teeth incorporate advanced metallurgy and precise manufacturing techniques to ensure consistent hardness and wear characteristics throughout the tooth body. This engineering approach results in teeth that maintain their cutting edge longer and provide reliable performance in demanding environments. The design also considers factors such as material flow and stress distribution, making them highly efficient in breaking and moving hard materials while protecting the bucket and excavator from excessive wear and stress.