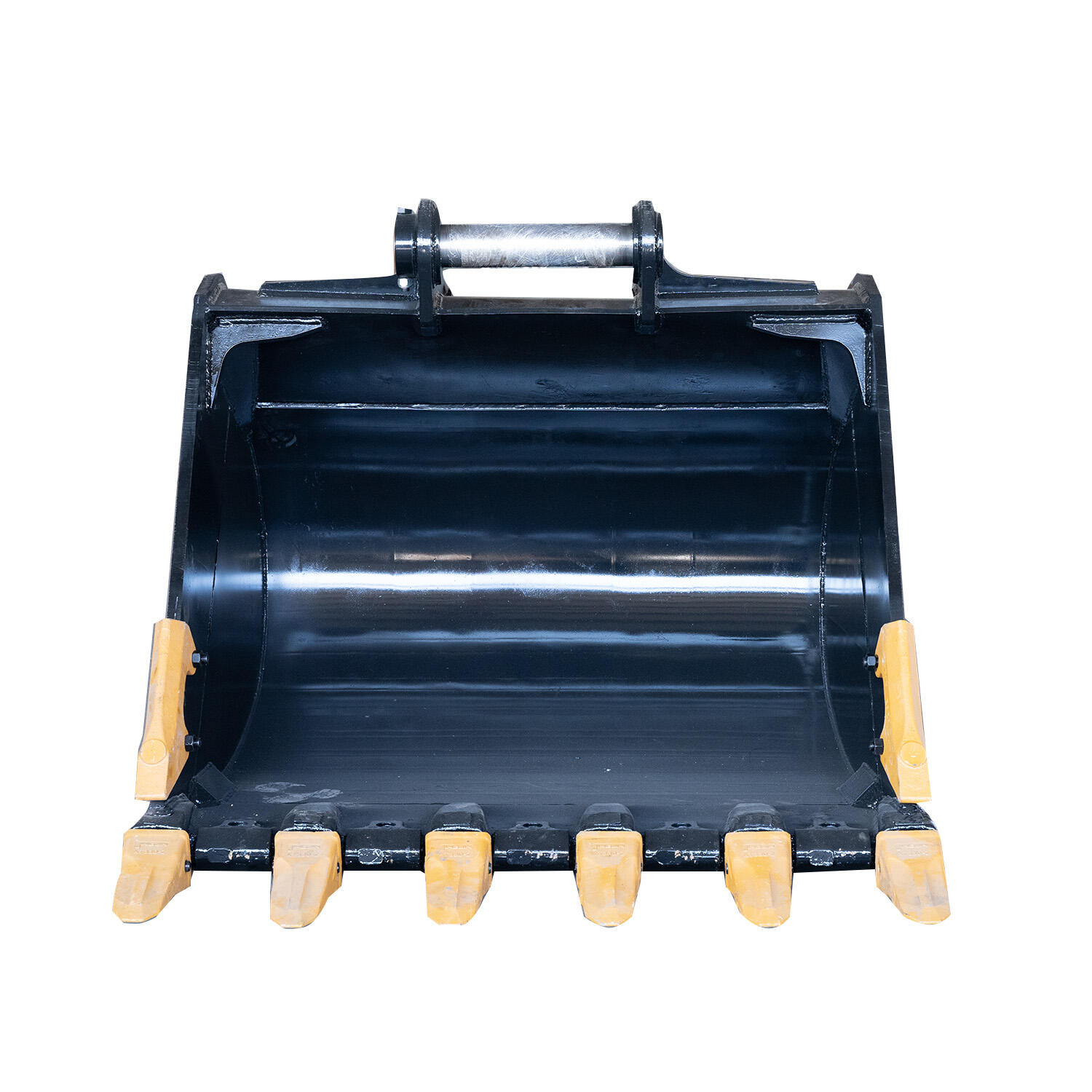

rock teeth for excavator bucket

Rock teeth for excavator buckets are essential components designed to enhance the digging and breaking capabilities of excavation equipment. These robust attachments are engineered from high-grade alloy steel, specifically formulated to withstand extreme wear and impact during heavy-duty operations. The teeth feature a self-sharpening design that maintains optimal penetration performance throughout their service life. They are strategically positioned along the bucket's cutting edge to maximize digging efficiency and material penetration. Each tooth consists of two main parts: the adapter, which is welded or bolted to the bucket lip, and the replaceable tooth point that engages directly with the material being excavated. The system employs a secure locking mechanism that ensures the teeth remain firmly in place during operation while allowing for quick replacement when necessary. These teeth are available in various shapes and sizes to suit different applications, from general earthmoving to specialized rock breaking. The design incorporates wear-resistant properties that extend operational life and reduce maintenance frequency, ultimately contributing to increased productivity and cost efficiency on construction sites, quarries, and mining operations.