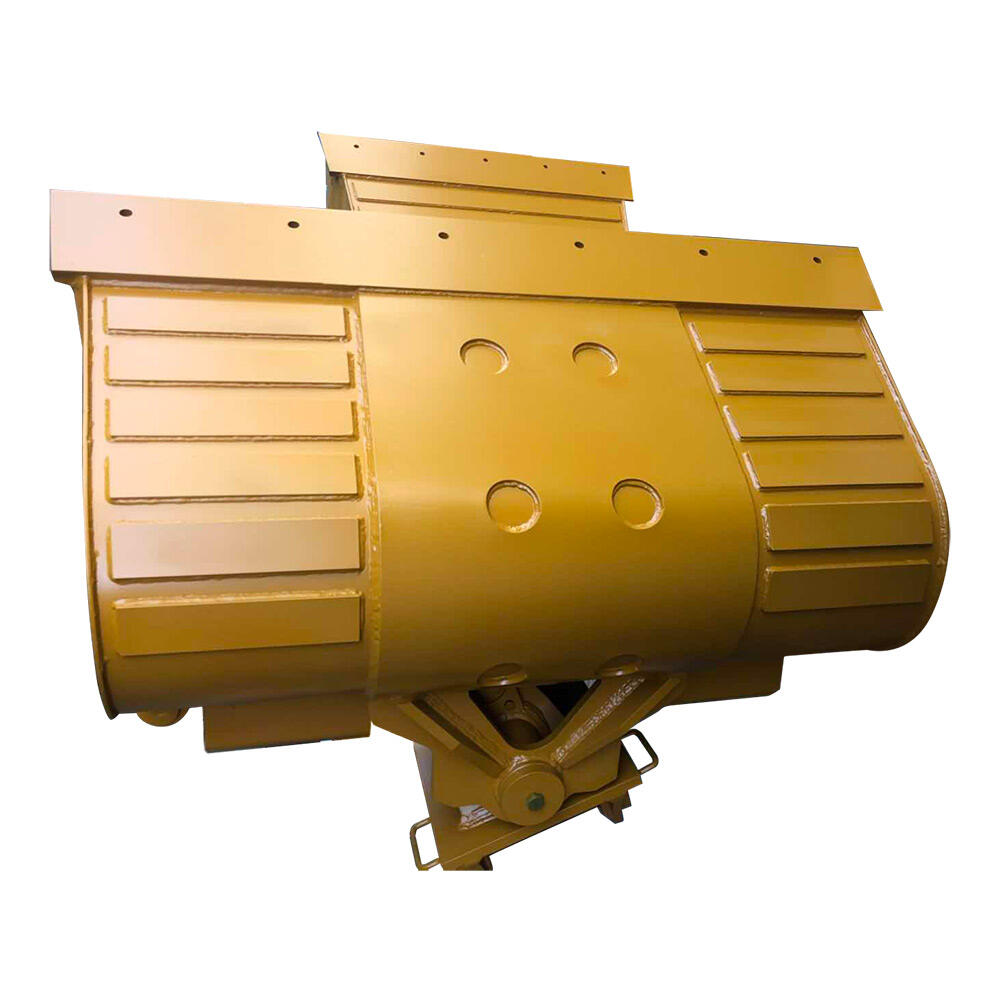

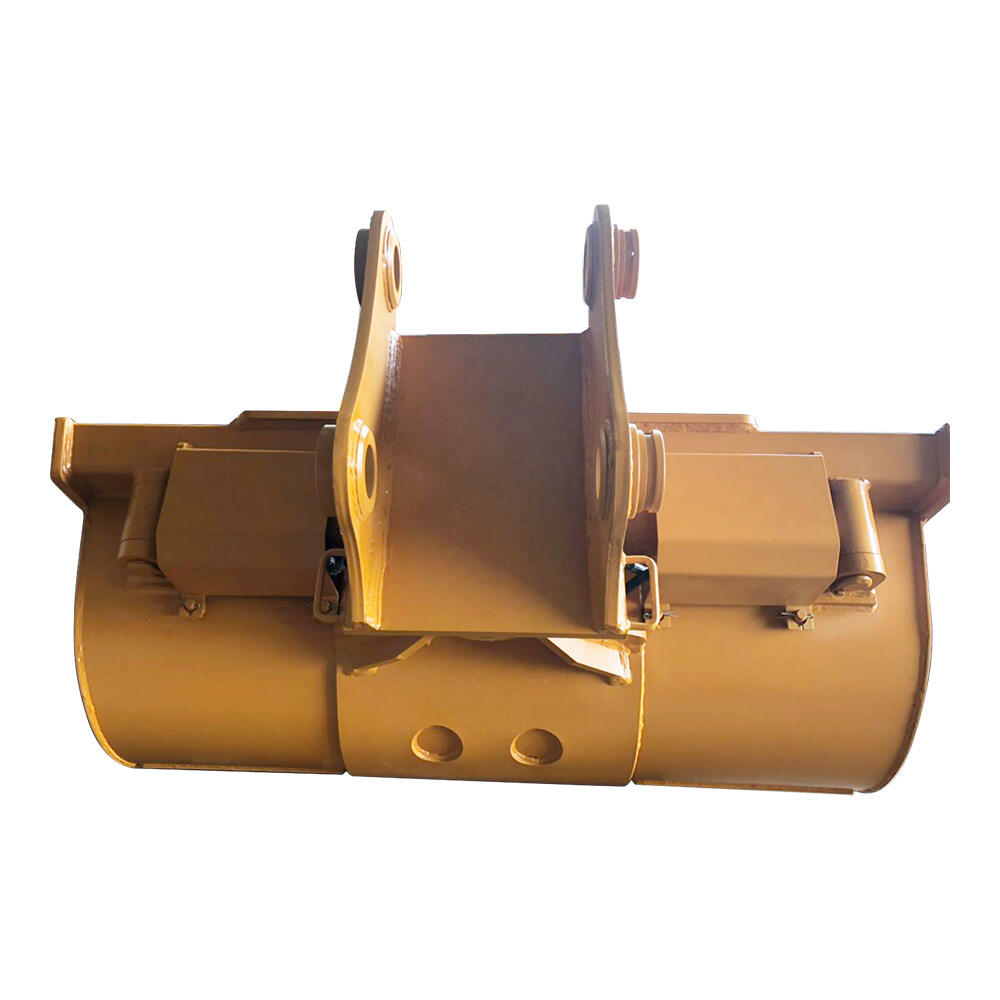

tilting mud bucket

A tilting mud bucket is a specialized piece of construction equipment designed to effectively handle, transport, and dispose of mud, slurry, and other wet materials on construction sites. This innovative attachment combines robust construction with advanced hydraulic systems to provide controlled tilting capabilities, enabling precise material placement and efficient waste management. The bucket features a reinforced steel construction with a carefully engineered center of gravity that facilitates smooth tilting operations while maintaining stability. Its design includes specially positioned pivot points and hydraulic cylinders that enable operators to achieve precise angles for optimal material discharge. The bucket's interior is typically coated with wear-resistant materials to extend its service life and features a sealed construction to prevent leakage of wet materials during transport. Available in various sizes to accommodate different machine capacities, these buckets are compatible with multiple types of construction equipment, including excavators, wheel loaders, and skid steers. The tilting mechanism can usually rotate up to 90 degrees, allowing for precise placement of materials and reducing the need for multiple positioning adjustments. Advanced models often incorporate features such as rubber seals to prevent material spillage, reinforced edge protection, and optimized bucket geometry for improved material flow characteristics.