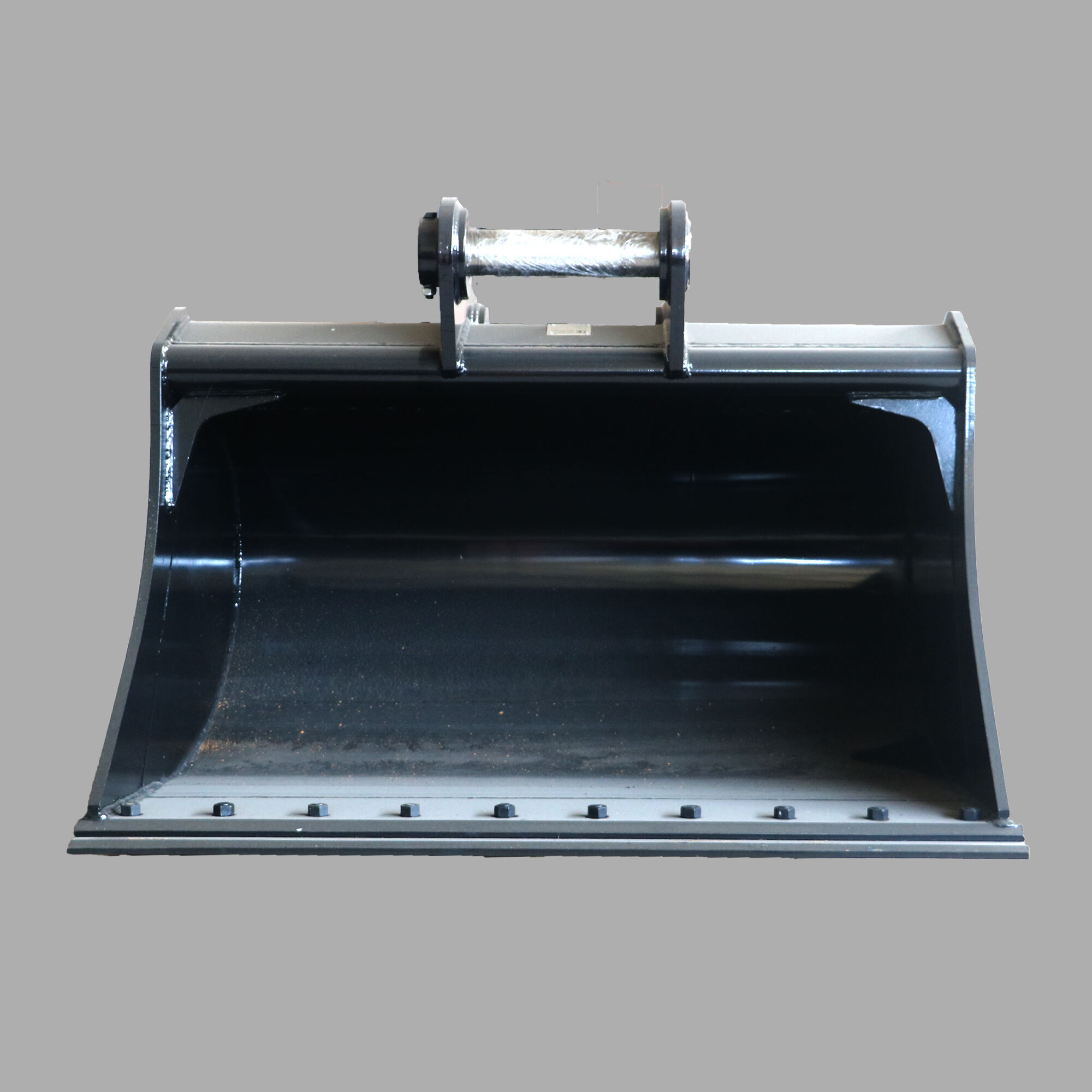

clean out bucket excavator

The clean out bucket excavator represents a specialized piece of construction equipment designed to efficiently remove debris, sediment, and materials from various work sites. This versatile attachment transforms standard excavators into powerful cleaning machines, featuring a unique design that combines robust construction with precision engineering. The bucket's structure includes reinforced sides, wear-resistant edges, and optimized capacity for maximum material handling. Its distinctive perforated design allows for effective separation of liquids and solids, making it particularly valuable in drainage operations, pond maintenance, and construction site cleanup. The equipment operates through a hydraulic system that enables smooth control and precise movement, essential for both delicate operations and heavy-duty cleaning tasks. With adjustable positioning capabilities, operators can effectively clean areas that are typically difficult to access, including corners, slopes, and narrow channels. The clean out bucket excavator proves invaluable across various applications, from construction and municipal works to agricultural and industrial cleaning projects, delivering consistent performance in challenging environments.