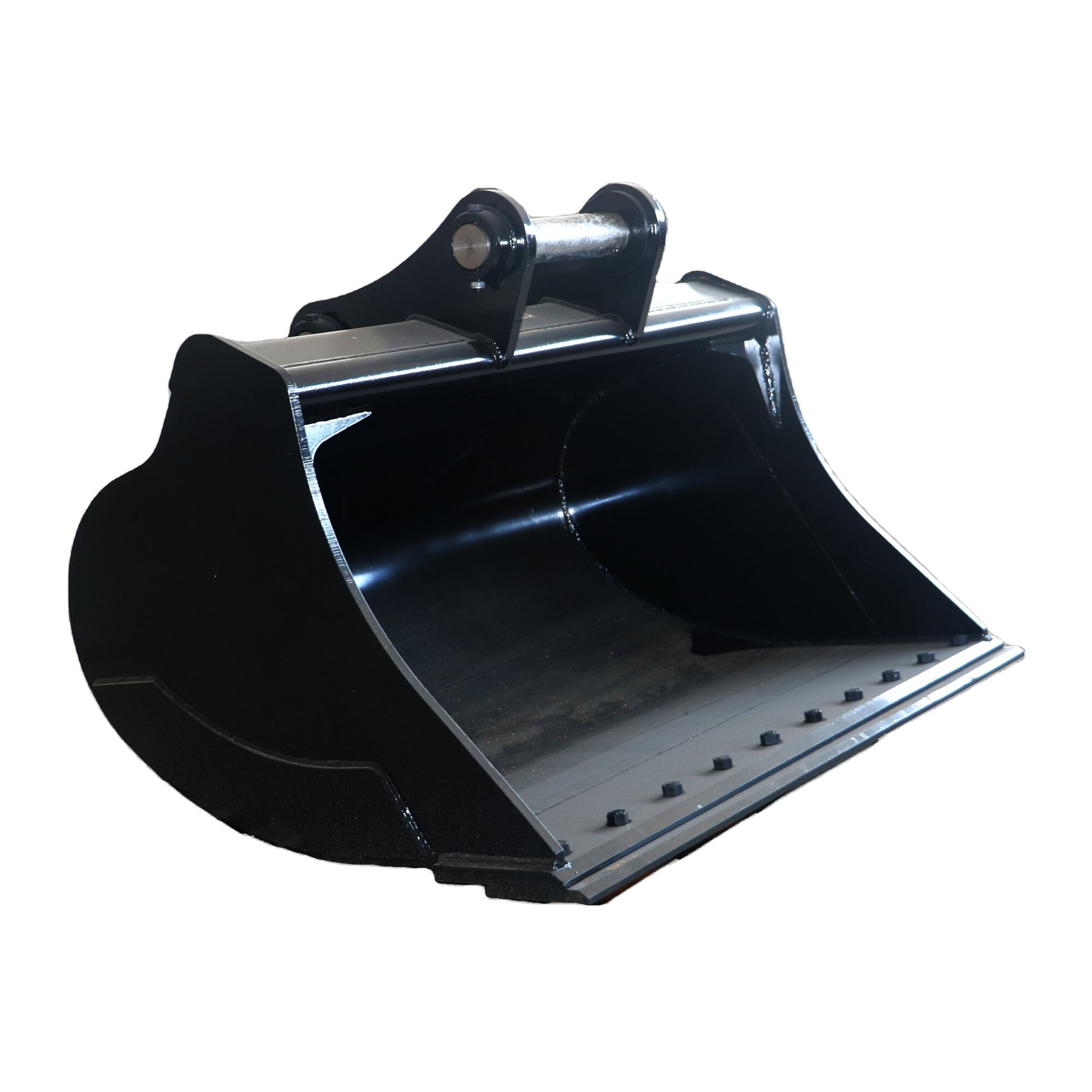

excavator cleaning bucket

The excavator cleaning bucket is a specialized attachment designed to enhance construction and excavation efficiency through its innovative cleaning and sorting capabilities. This versatile tool features a robust steel construction with strategically positioned drainage holes that allow for effective material separation while retaining valuable resources. The bucket's design incorporates parallel bars with precise spacing, enabling operators to sift through various materials efficiently, separating debris from reusable aggregate. Advanced engineering ensures optimal weight distribution and balance during operation, while reinforced edges provide extended durability in demanding conditions. The cleaning bucket seamlessly integrates with standard excavator mounting systems, making it compatible with a wide range of equipment sizes. Its applications span across construction, demolition, recycling, and landscaping industries, where it excels in tasks such as topsoil screening, waste material sorting, and aggregate cleaning. The bucket's innovative design also includes replaceable wear parts, ensuring long-term cost-effectiveness and maintaining peak performance throughout its service life.