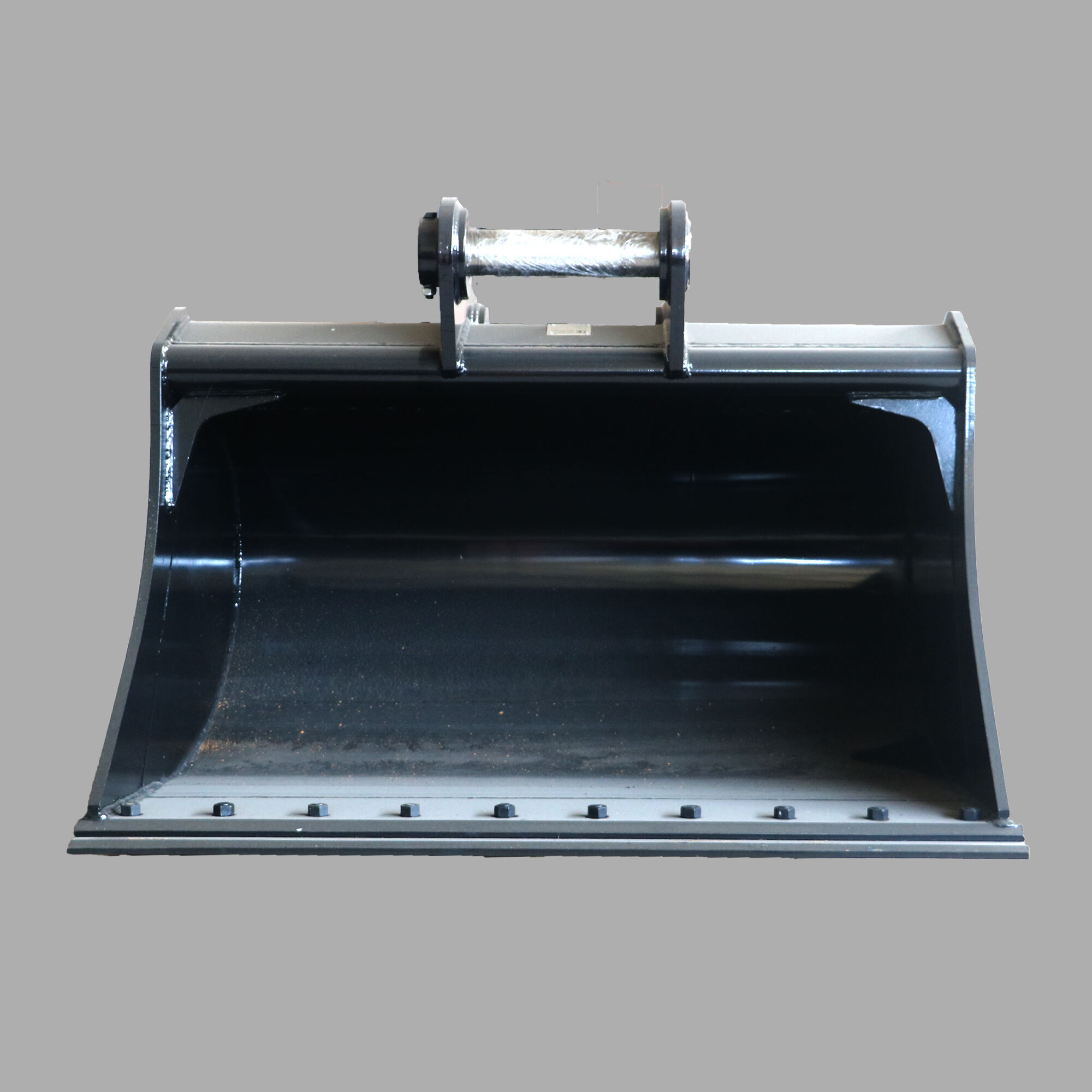

clean up bucket mini excavator

The clean up bucket mini excavator represents a revolutionary advancement in compact construction equipment, designed specifically for efficient material handling and site cleanup operations. This versatile attachment transforms standard mini excavators into highly efficient cleaning machines, featuring a specialized bucket design that excels at collecting and sorting various materials. The bucket's innovative construction includes reinforced edges and a precision-engineered slope that optimizes material collection while minimizing ground damage. Built with high-strength steel and featuring replaceable wear parts, these buckets offer exceptional durability even under demanding conditions. The attachment's design incorporates advanced hydraulic systems that enable smooth operation and precise control, making it ideal for both delicate cleanup tasks and heavy-duty material handling. The clean up bucket's width is carefully calculated to maximize efficiency while maintaining maneuverability in confined spaces. Its unique shape allows for effective sweeping motions, enabling operators to gather debris and materials efficiently while maintaining site cleanliness. The bucket's integration with mini excavators creates a powerful combination that significantly reduces manual labor requirements and increases productivity across various applications, from construction sites to landscaping projects.