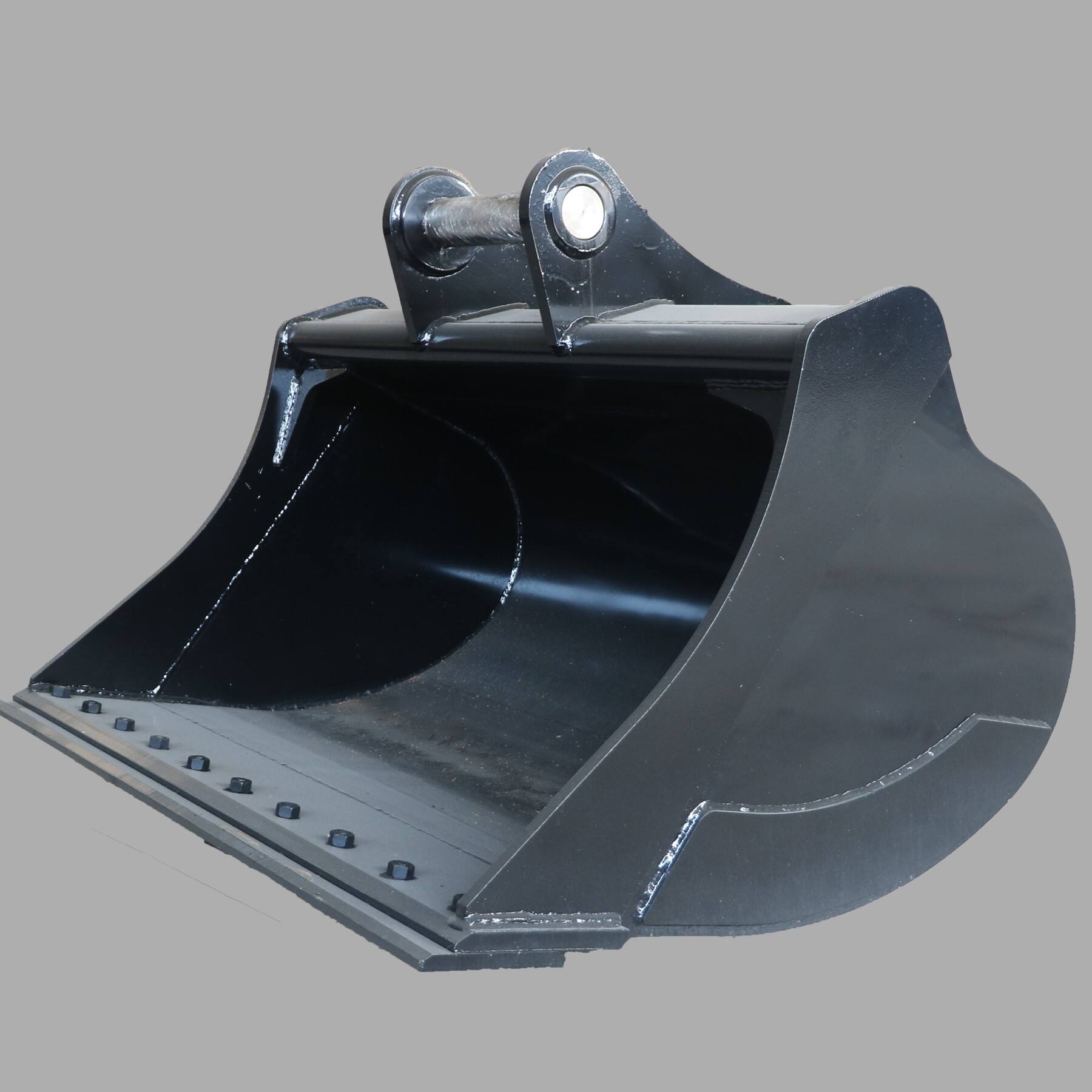

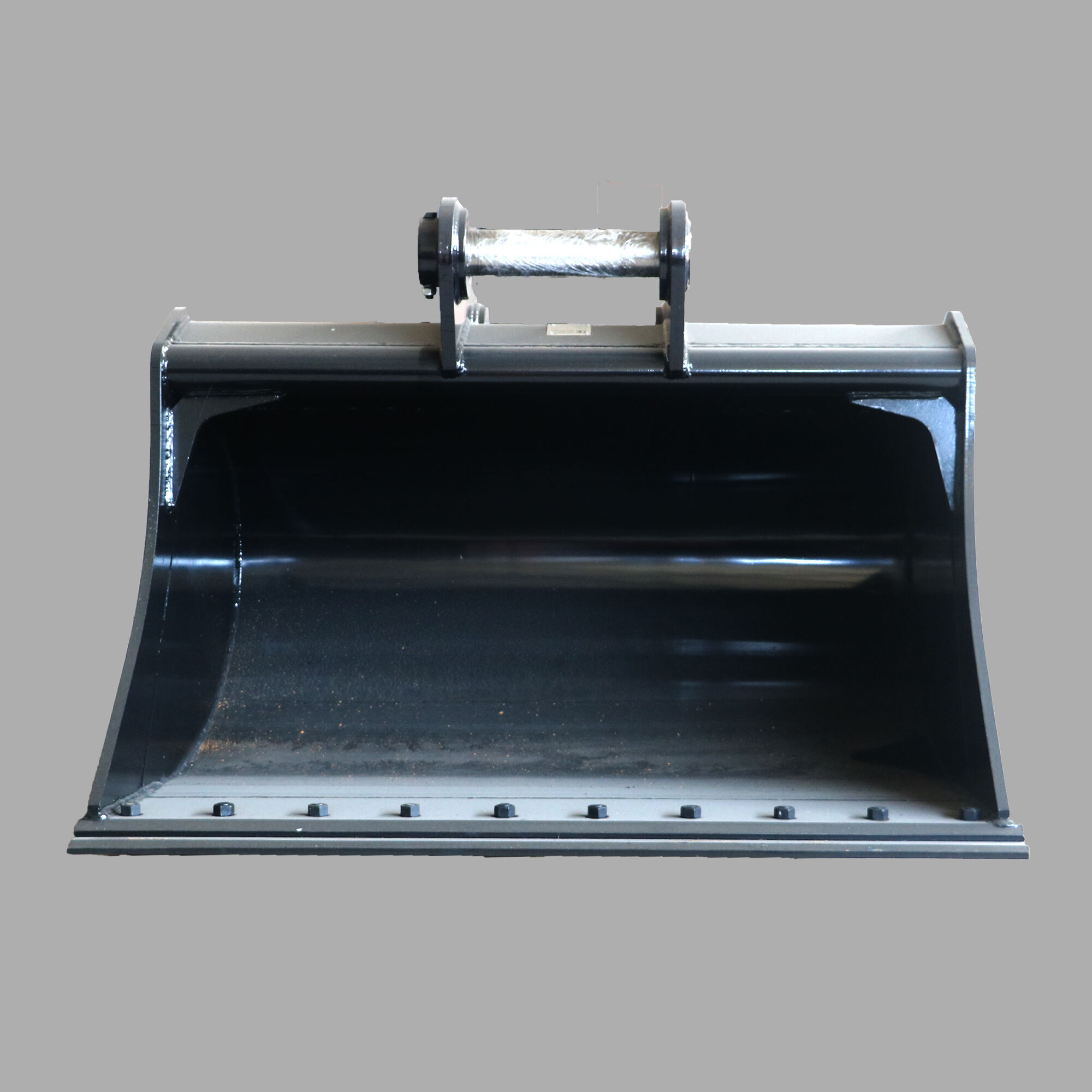

clean up bucket excavator

The clean up bucket excavator represents a significant advancement in construction and excavation equipment, designed specifically for efficient material handling and site cleanup operations. This specialized attachment transforms standard excavators into versatile cleaning machines, featuring a unique bucket design that combines traditional excavation capabilities with advanced filtering mechanisms. The bucket's structure incorporates carefully spaced bars or mesh patterns that allow fine materials like soil to pass through while retaining larger debris, rocks, and construction materials. This innovative design enables operators to separate and sort materials directly during the excavation process, significantly reducing the time and effort required for site cleanup. The clean up bucket excavator excels in various applications, including construction site management, demolition cleanup, landscaping projects, and waste sorting operations. Its robust construction typically features high-grade steel components, reinforced edges, and wear-resistant materials to ensure durability in demanding conditions. The attachment's design also includes optimal weight distribution and balance considerations, allowing for smooth operation and precise control during material handling tasks. Modern versions often incorporate hydraulic systems that enhance the bucket's functionality, enabling features such as adjustable screening sizes or automated shaking mechanisms for more efficient material separation.